The straight shank twist drill is a widely used cutting tool designed to create cylindrical holes in various materials such as metal, wood, and plastic. Its design features a cylindrical shank that fits securely into drill chucks, providing stability during operation. The twist drill's cutting edges are formed by helical grooves, which help remove chips efficiently and allow coolant to reach the cutting surface. This mechanism enhances drilling accuracy and reduces wear.

One of the advantages of a straight shank twist drill is its versatility. It is suitable for use in hand drills, drill presses, and CNC machines, making it a common choice in workshops and manufacturing settings. The straight shank design allows for easy replacement and compatibility with a wide range of drilling equipment.

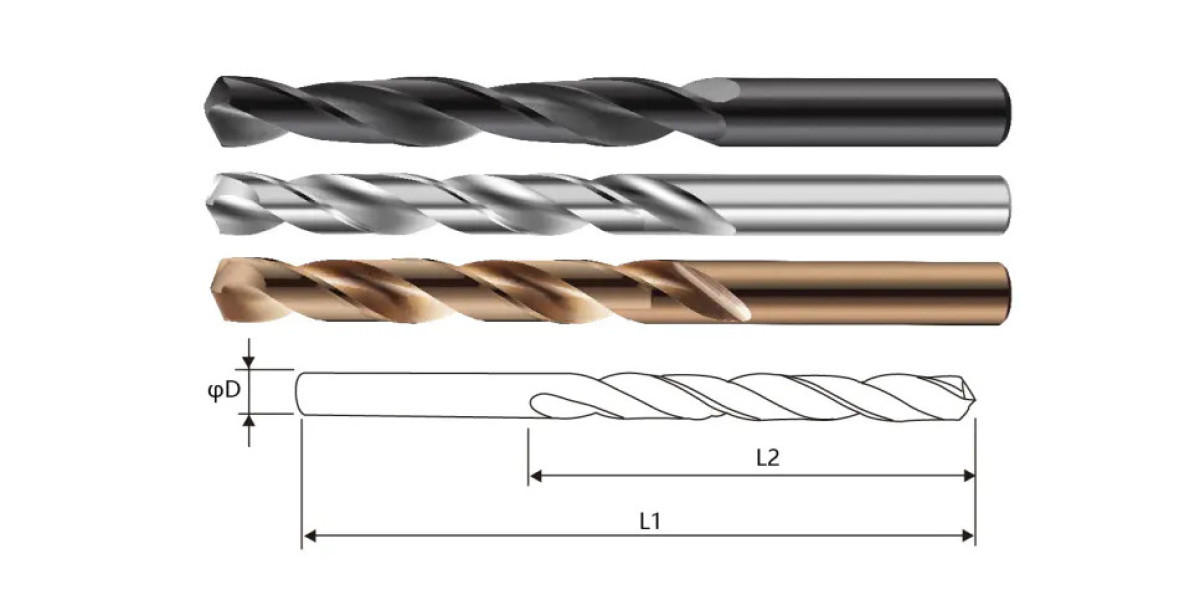

When selecting a straight shank twist drill, factors such as material composition, diameter, and flute length should be considered. Materials like high-speed steel (HSS) or cobalt alloys are frequently used for these drills, providing resistance to heat and wear during cutting. The drill's geometry, including point angle and flute shape, also affects performance and chip evacuation.

Proper maintenance and handling of the straight shank twist drill can extend its service life. Regular sharpening and cleaning help maintain cutting efficiency and reduce the risk of tool failure. Additionally, using the correct feed rate and speed for the material being drilled contributes to better results and tool longevity.

Overall, the straight shank twist drill is a reliable tool that offers consistent performance across various drilling tasks. Its design and material options make it adaptable to many industrial and hobbyist applications.