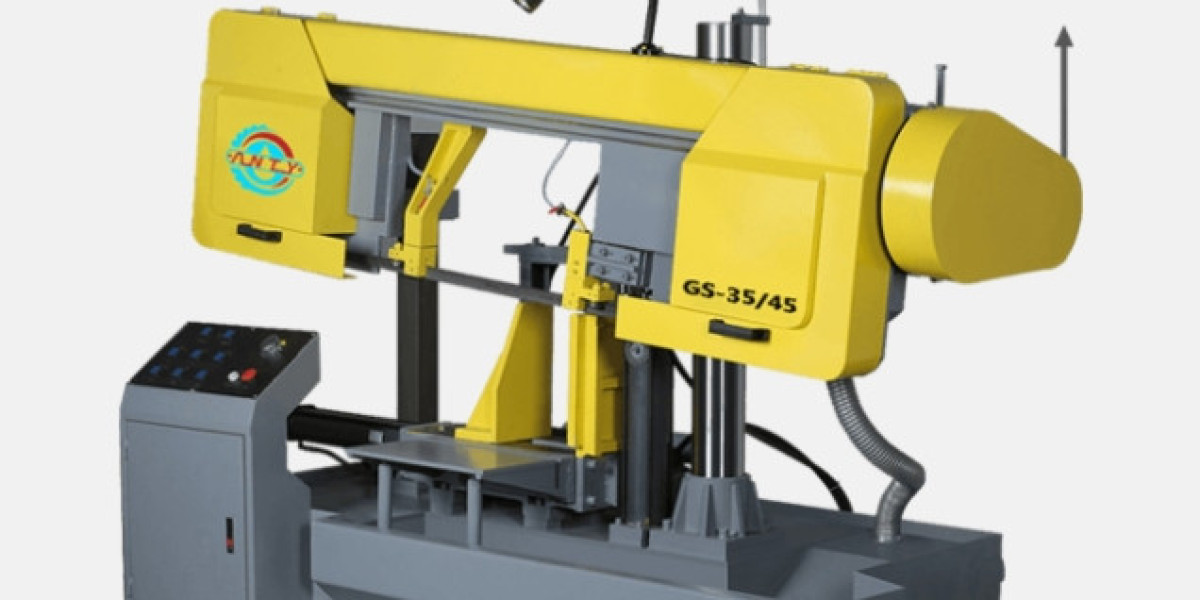

Regular maintenance of the Horizontal Metal Cutting Band Sawing Machine is essential for sustaining its performance and ensuring safe operation. While this equipment is built for durability, consistent care helps avoid unexpected breakdowns, extends the lifespan of components, and supports cutting accuracy over time.

One of the most important areas to monitor is the saw blade. The blade should be inspected before each shift for signs of wear, dullness, or damage. A worn-out blade can produce rough cuts, slow down the cutting process, and increase stress on the motor. Operators should be trained to recognize when the blade needs replacement and how to install it properly.

Lubrication is also critical. Key areas, including the blade guides, hydraulic cylinders, and drive bearings, require proper lubrication to operate smoothly. Lack of lubrication can lead to friction, overheating, and premature wear. Establishing a weekly lubrication schedule ensures these parts stay in good working condition.

The alignment of the blade should be checked regularly. Over time, vibrations and general use may cause slight shifts that affect the straightness of the cut. A misaligned blade can lead to inaccurate results and blade binding. Recalibrating the alignment is a straightforward process but should be handled with care.

Coolant systems must also be maintained. The Horizontal Metal Cutting Band Sawing Machine typically uses coolant to minimize heat buildup during cutting. Operators should ensure that the coolant reservoir is filled and that the fluid is clean and flowing properly. Dirty coolant can clog the nozzles and leave residue on the material surface.

Another important task is cleaning. Metal chips accumulate around the blade area, feed table, and internal compartments. These chips can interfere with machine function and contribute to overheating. Cleaning the machine at the end of each day helps maintain smooth operation and prevents buildup in moving parts.

Hydraulic components, if included, should be inspected for leaks or pressure inconsistencies. Low fluid levels or damaged seals can compromise feed control, resulting in jerky or uneven cutting motion. Replacing seals and topping up fluid when needed ensures the system continues to perform correctly.

Lastly, electrical connections and safety switches should be tested periodically. Emergency stop functions, power switches, and control panels need to remain responsive. Faulty electrical components can lead to safety hazards and interrupt production.

By setting up a structured maintenance plan, businesses can keep their Horizontal Metal Cutting Band Sawing Machine in top condition. Not only does this enhance productivity, but it also helps prevent unplanned expenses related to repairs or replacements.