In the world of electrical components, precision and reliability are critical. A Customized Mold for Relay Socket ensures that each unit meets exact specifications, providing consistent performance in various applications. Unlike generic molds, a tailored solution accounts for unique design requirements, material properties, and functional demands. This level of customization improves durability and reduces the risk of failure in critical systems.

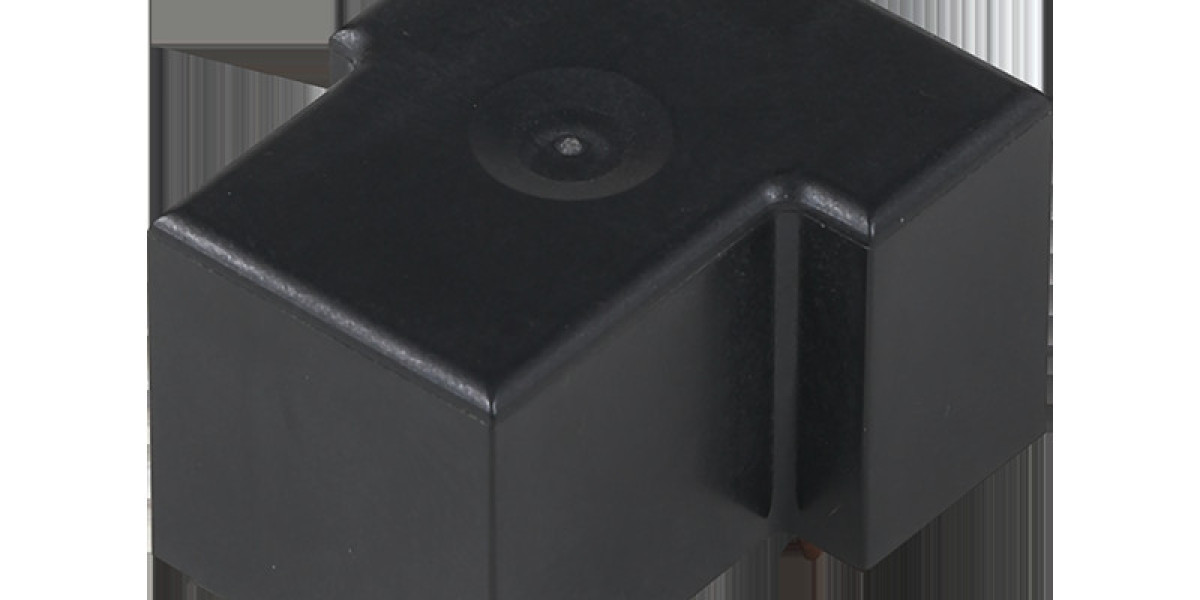

One of the primary advantages of a Customized Mold for Relay Socket is its ability to accommodate specific dimensions. Relay sockets come in different shapes and sizes, and a one-size-fits-all approach often leads to compatibility issues. By using a tailored mold, manufacturers can produce relay sockets that fit seamlessly into their intended assemblies. This precision minimizes installation errors and enhances the overall efficiency of electrical systems.

Material selection is another area where a Customized Mold for Relay Socket proves invaluable. Depending on the application, relay sockets may need to withstand high temperatures, corrosive environments, or mechanical stress. A bespoke mold allows for the use of specialized polymers or composites that offer superior resistance to these conditions. This adaptability ensures long-term performance, even in demanding industrial settings.

The production process also benefits from a Customized Mold for Relay Socket. Standard molds may require additional machining or manual adjustments, increasing production time and costs. A dedicated mold eliminates these inefficiencies by producing components that meet exact specifications from the first run. This reduces waste and accelerates time-to-market for new products.

Beyond manufacturing advantages, a Customized Mold for Relay Socket enhances product reliability. Poorly fitted or low-quality relay sockets can lead to electrical failures, posing safety risks. A precision-engineered mold ensures tight tolerances and uniform quality across all units. This consistency is crucial for industries where electrical stability is non-negotiable, such as automotive, aerospace, and energy sectors.

Innovation in mold design further expands the capabilities of a Customized Mold for Relay Socket. Advanced techniques like 3D printing and computer-aided design enable intricate geometries that were previously unattainable. These innovations allow for better heat dissipation, improved conductivity, and compact designs without compromising performance.

Investing in a Customized Mold for Relay Socket offers numerous benefits, from improved fit and material compatibility to streamlined production and enhanced reliability. Manufacturers seeking to optimize their electrical components should consider the advantages of a tailored solution. By prioritizing precision and adaptability, businesses can deliver superior products that meet the evolving demands of modern industries.