The mass production of disposable drinking vessels relies heavily on the precision and efficiency of the plastic cup mould, a fundamental tool in injection molding manufacturing. This specialized mold is engineered to form molten plastic into specific cup shapes with consistent wall thickness, structural integrity, and precise dimensional accuracy. The design and construction of a plastic cup mould require advanced engineering knowledge and sophisticated machining capabilities to create cavities that will produce thousands of identical cups per hour in high-volume production environments. The quality of the final plastic product is directly dependent on the precision of the plastic cup mould, making it a critical component in the manufacturing process for single-use drink containers used in food service, hospitality, and healthcare industries worldwide.

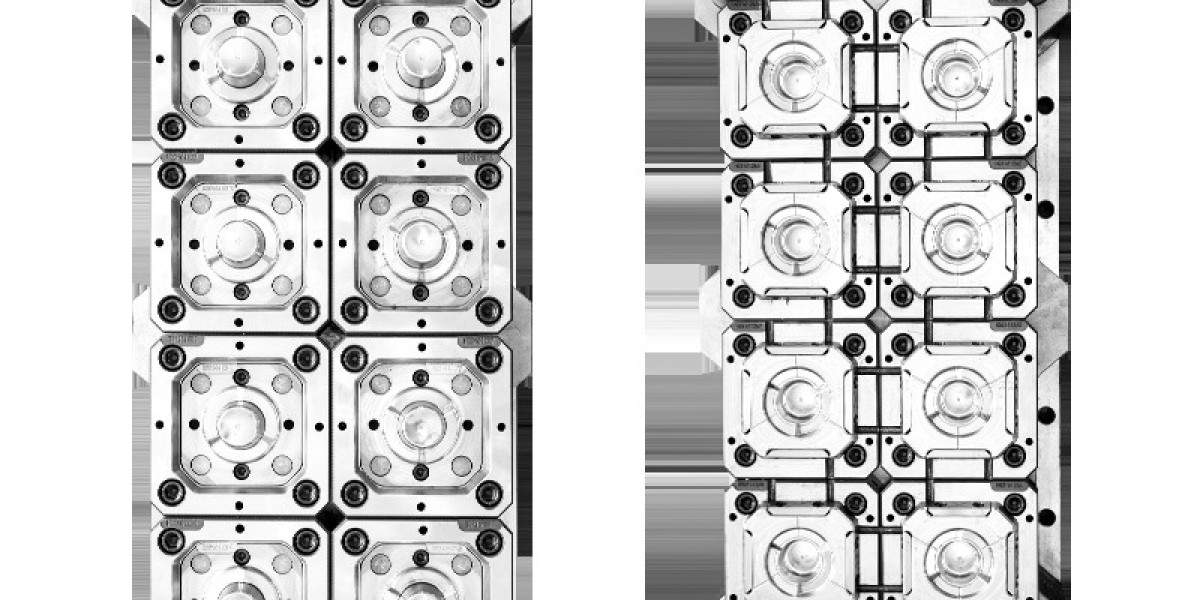

The manufacturing process for a plastic cup mould begins with detailed design specifications that account for the cup's intended capacity, structural requirements, stacking features, and aesthetic details. Mold designers use computer-aided design (CAD) software to create precise 3D models of the mold cavities, cores, and ejection systems. The actual plastic cup mould is typically constructed from hardened tool steel or aluminum, with the choice of material depending on production volume requirements and budget considerations. CNC machining centers mill the negative impression of the cup design into the mold blocks with extremely tight tolerances, often within microns, to ensure consistent product quality. Additional components such as guide pins, ejector pins, cooling channels, and venting systems are incorporated into the plastic cup mould design to facilitate efficient production cycles and prevent defects in the finished cups.

The operation of a plastic cup mould involves a carefully controlled injection molding process where thermoplastic material is heated to a liquid state and injected under high pressure into the mold cavity. The design of the plastic cup mould includes complex cooling channels that circulate temperature-controlled water to solidify the plastic quickly before the mold opens to eject the finished cup. The cycle time—the period required to complete one injection, cooling, and ejection sequence—is heavily influenced by the efficiency of the plastic cup mould's thermal management system. Proper maintenance of the plastic cup mould is essential for prolonged service life, including regular cleaning of resin residues, inspection of moving components, and polishing of cavity surfaces to maintain product quality. The continuous innovation in plastic cup mould technology enables manufacturers to produce increasingly sophisticated cup designs with improved material efficiency and production speeds.