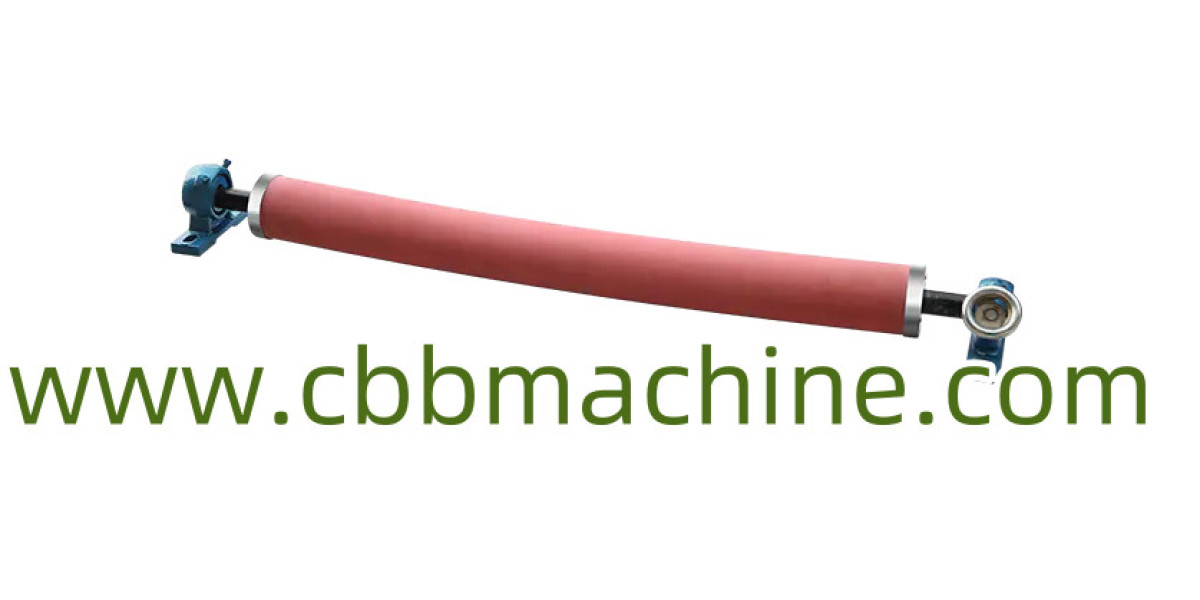

Banana Rollers are an integral part of modern fruit processing lines, designed to transport and align bananas gently during various stages of production. By ensuring smooth movement and minimizing bruising, these rollers help maintain the quality of the fruit, which is essential for both fresh market distribution and processing into other products.

One of the key advantages of using this equipment is the reduction in manual handling. Traditionally, workers would need to sort, align, and transport bananas by hand, which can lead to inconsistencies, higher labor costs, and potential damage to the fruit. By incorporating rollers into the production line, bananas are consistently guided along the correct path, improving efficiency and maintaining product integrity.

The versatility of these rollers allows them to be adapted for different line configurations. Whether used for short-distance transfers, grading stations, or packaging areas, the rollers can be arranged in a way that suits the unique needs of each facility. Customizable options also make it possible to accommodate varying banana sizes, ensuring that all fruits receive uniform treatment regardless of their dimensions.

In addition to operational efficiency, proper design also enhances safety. Automated transport systems reduce the need for workers to lift and carry heavy loads, which minimizes the risk of workplace injuries. Additionally, the rollers are constructed to avoid pinching points or sharp edges, providing a secure environment for employees operating around the machinery.

Maintenance is straightforward, as components are typically accessible for inspection and cleaning. Regular checks help maintain smooth rotation, prevent misalignment, and extend the service life of the equipment. The use of durable materials ensures that the rollers withstand constant use in environments where moisture and fruit acids are present.

Beyond handling efficiency and safety, integrating rollers into fruit processing lines supports better quality control. By maintaining consistent orientation and spacing, bananas can be inspected more easily for defects, ripeness, or size categories. This allows for more accurate sorting, better packaging results, and a higher-quality end product for consumers.

Investing in reliable fruit handling solutions like these contributes to operational consistency and long-term profitability. For businesses seeking to optimize their banana processing lines while protecting product quality, Banana Rollers offer an effective and adaptable option that meets the practical demands of modern operations.

For more information on customizable banana rollers, visit https://www.cbbmachine.com/product/banana-roller/