In roll-to-roll manufacturing systems, a Differential Air Shaft is essential for achieving consistent tension and smooth operation across multiple winding cores. Maintaining proper web control ensures high-quality output in industries such as paper, film, textiles, and flexible packaging, while minimizing material waste and operational issues.

A primary advantage of this equipment lies in its ability to evenly distribute torque among several rolls. Without precise tension control, unwinding large rolls into smaller ones can result in wrinkles, breakage, or misalignment. Using pneumatic pressure and internal mechanical design, it allows each roll to rotate at the correct speed while maintaining uniform tension, improving both product quality and production efficiency.

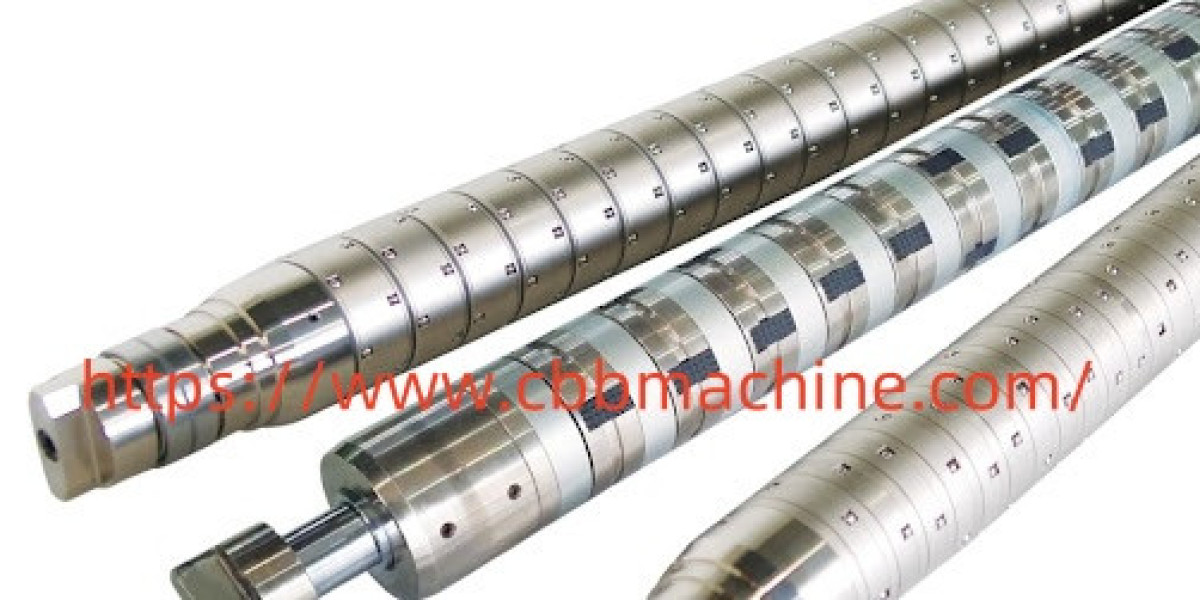

Durability and robust construction are also important considerations. High-quality materials allow the shaft to endure the repeated stresses of continuous operation without deforming or losing functionality. The air chamber and differential mechanism are carefully engineered to provide smooth engagement, reliable rotation, and long service life, reducing the need for frequent maintenance or unexpected downtime.

Integration with existing machinery is another key benefit. These shafts are typically compatible with a variety of unwinders and rewinders, making them a flexible choice for factories seeking to upgrade or optimize operations. Minimal modifications are needed for installation, allowing production lines to maintain efficiency during upgrades.

Operator safety and convenience are also addressed through thoughtful design. Controlled tension reduces the risk of rolls slipping, while ergonomic features such as air controls and quick-release mechanisms make it easier for workers to handle materials. This not only improves productivity but also creates a safer working environment.

The applications of this technology span numerous industries. In printing, it maintains precise alignment and consistent color reproduction over long runs. In packaging, it prevents material damage during unwinding and rewinding processes. In textiles and film production, it supports high-speed continuous operation while protecting delicate materials, ensuring overall product quality remains uncompromised.

In conclusion, this component serves as a vital element in modern roll-based production lines. By promoting efficiency, safety, and product consistency, it plays a crucial role in maintaining smooth industrial operations. For detailed information about its key components, applications, and benefits, visit https://www.cbbmachine.com/news/industry-news/differential-air-shafts-key-components-applications-benefits-and-more.html