A Cast Steel Gate Valve Manufacturer plays a crucial role in supplying industries with reliable valve solutions that control the flow of liquids and gases. Cast steel gate valves are widely used in pipelines for their strength, durability, and ability to handle high-pressure systems. The expertise of a Cast Steel Gate Valve Manufacturer determines the quality, performance, and longevity of these valves, which are essential for industrial safety and efficiency.

One key focus for a Cast Steel Gate Valve Manufacturer is material selection. High-quality cast steel provides the necessary strength and resistance to pressure, corrosion, and temperature variations. By choosing appropriate grades of steel and adhering to strict production standards, the manufacturer ensures that each valve meets the operational demands of industrial systems.

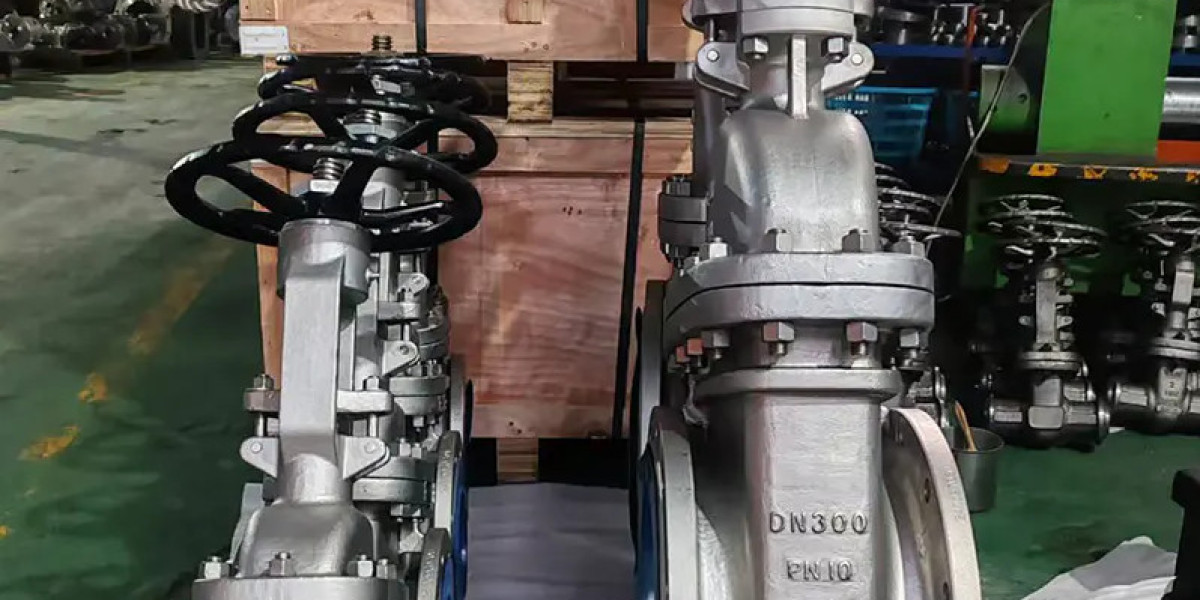

Design and engineering are also critical components for a Cast Steel Gate Valve Manufacturer. The valve's structure, including the gate, stem, and sealing surfaces, must be precisely engineered to prevent leaks and provide smooth operation. Manufacturers often employ advanced machining and casting techniques to achieve consistent tolerances and reliable performance in every product.

Durability is another important consideration. A Cast Steel Gate Valve Manufacturer designs valves to withstand harsh environments, including chemical plants, oil and gas pipelines, and power generation facilities. The robust construction of cast steel gate valves allows them to endure high pressure, temperature fluctuations, and mechanical stress without compromising functionality.

A Cast Steel Gate Valve Manufacturer also emphasizes testing and quality control. Each valve typically undergoes rigorous inspection and pressure testing to ensure it meets industry standards and client specifications. This process helps prevent failures during installation and operation, giving industrial operators confidence in the valve's reliability.

Installation and maintenance are additional areas where a Cast Steel Gate Valve Manufacturer provides guidance. Proper installation ensures that the valve functions efficiently, while routine maintenance and lubrication help extend its service life. Manufacturers often provide manuals, training, and support to ensure that clients can operate and maintain the valves correctly.

Flexibility in production is also a feature of a Cast Steel Gate Valve Manufacturer. Valves can be customized in terms of size, pressure rating, and connection type to suit various industrial applications. This adaptability ensures that clients receive solutions tailored to their specific requirements, whether for new construction projects or retrofitting existing systems.

Environmental considerations are increasingly relevant for a Cast Steel Gate Valve Manufacturer. By optimizing manufacturing processes and using materials responsibly, manufacturers can reduce waste and energy consumption while maintaining the quality and reliability of cast steel gate valves.

A Cast Steel Gate Valve Manufacturer combines material expertise, engineering precision, and quality control to produce valves suitable for demanding industrial environments. Their focus on durability, reliability, and customization ensures that cast steel gate valves provide consistent performance and safety in a wide range of applications. Working with a reputable manufacturer allows industries to maintain efficient and secure operations while relying on high-quality valve solutions.